Looking for professional metal gate repair in Walnut Creek, CA? Get a detailed, step-by-step guide on the repair process, common issues, and expert solutions to restore your gate’s functionality and security.

A properly functioning metal gate is essential for residential and commercial properties, ensuring security, privacy, and aesthetic appeal. However, due to continuous use, weather exposure, and general wear and tear, metal gates can develop issues that need professional attention. Whether it’s a rusty hinge, a malfunctioning motor, or a misalignment, timely repairs are crucial to maintaining the gate’s performance and longevity.

If you’re looking for reliable metal gate repair in Walnut Creek, CA, understanding the repair process can help you make informed decisions. This guide provides a comprehensive step-by-step breakdown of the repair process, from diagnosing common problems to executing effective repairs. Whether you are a homeowner, a business owner, or a property manager, this article will equip you with the essential knowledge to ensure your gate remains in top condition.

Common Issues with Metal Gates in Walnut Creek, CA

Rust and Corrosion

One of the most prevalent problems with metal gates is rust and corrosion, particularly in regions with high humidity, frequent rainfall, or exposure to salty air. Rust occurs when moisture and oxygen interact with the metal, leading to oxidation, which weakens the structure over time. If left untreated, rust can cause severe deterioration, compromising the gate’s strength and functionality. Preventative maintenance, such as applying rust-resistant coatings, regular inspections, and repainting, can help mitigate this issue.

Misalignment and Sagging

Over time, metal gates may experience misalignment or sagging, which can be caused by various factors such as ground shifting, prolonged exposure to heavy loads, loose hinges, or deteriorating mounting hardware. A sagging gate can become difficult to open and close, leading to inconvenience and potential security vulnerabilities. In extreme cases, the gate may no longer latch or lock properly, requiring repairs or reinforcement. Regular adjustments, hinge tightening, and ensuring the foundation remains stable can help prevent these issues.

Mechanical Failures in Automatic Gates

Automatic metal gates provide convenience and enhanced security but come with their own set of challenges. These gates rely on motors, sensors, control panels, and other electronic components to function. Electrical failures, motor burnout, sensor misalignment, and worn-out wiring can result in operational issues, making the gate unresponsive or malfunctioning. Additionally, power outages can render an automatic gate temporarily useless unless it has a backup power source. Routine maintenance, checking electrical connections, and keeping moving parts lubricated can help extend the life of the automation system.

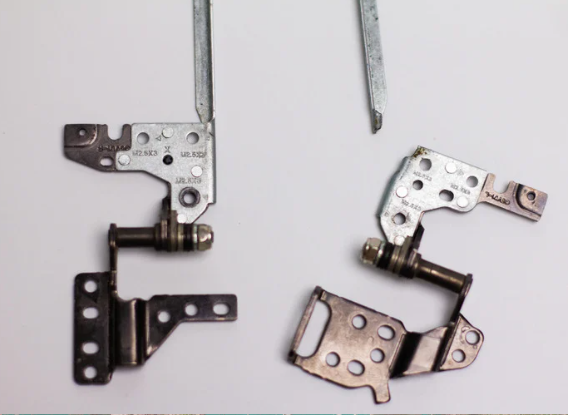

Broken or Worn Hinges

Hinges are essential for the proper movement of swing gates. With regular use, they can become worn out, rusted, or even broken, causing the gate to stick, squeak, or fail to close properly. If the hinges weaken significantly, the gate may sag or detach from its frame, posing a security risk. To prevent hinge-related problems, it is important to lubricate them periodically, replace any worn-out parts, and use high-quality, weather-resistant materials for long-lasting durability.

Damaged Gate Tracks and Rollers

For sliding metal gates, the condition of the tracks and rollers is crucial for smooth operation. Over time, dirt, debris, or leaves can accumulate in the tracks, obstructing movement. Additionally, tracks can become warped, bent, or misaligned due to constant wear and tear, heavy usage, or external impacts. Rollers may also wear down, develop cracks, or seize up, leading to resistance when trying to slide the gate open or closed. Regular cleaning, realigning the tracks, and replacing worn-out rollers are essential maintenance tasks to keep the gate functioning efficiently.

Step-by-Step Guide to Metal Gate Repair

Inspection and Diagnosis

Before any repair work begins, a detailed inspection is crucial to determine the issue’s root cause and assess the metal gate’s overall condition. A professional technician will perform the following tasks:

- Check for visible signs of damage – Look for rust, corrosion, cracks, dents, or bent components that could compromise the gate’s structural integrity.

- Assess hinge alignment and track conditions – Ensure that hinges are properly secured and that the gate is not sagging or misaligned. For sliding gates, track conditions will be examined for obstructions or warping.

- Inspect electrical components in automatic gates – For electric gates, wiring, motors, sensors, and control systems will be checked for signs of wear, disconnection, or malfunction.

- Test the opening and closing mechanisms – The gate will be manually and automatically operated to identify any resistance, grinding noises, or jerky movements that indicate mechanical issues.

Rust Removal and Prevention

Rust is one of the most common problems with metal gates, particularly in humid or rainy environments. If rust is detected, the following steps are taken to restore and protect the gate:

- Surface Preparation – The affected area is thoroughly cleaned to remove loose rust, dirt, and old paint.

- Sanding or Grinding – Wire brushes, sandpaper, or power tools are used to remove rust spots and smoothen rough patches.

- Applying a Rust Converter – A rust-neutralizing chemical is applied to stop further corrosion and prepare the surface for painting.

- Protective Coating – A rust-resistant primer is applied, followed by high-quality metal paint or powder coating to prevent future rust formation and enhance durability.

- Regular Maintenance – To prevent recurring rust, regular cleaning, waxing, and touch-ups are recommended.

Hinge and Alignment Repairs

If the gate is sagging, misaligned, or difficult to open and close, hinge and alignment repairs are necessary. Professionals will:

- Tighten or Replace Loose Hinges – Over time, hinges may become loose due to wear and tear or environmental factors. Securely tightening them or replacing damaged hinges can improve functionality.

- Adjust the Gate Post or Mounting Brackets – Ensuring that the gate is properly aligned with the frame prevents unnecessary strain on hinges and enhances smooth operation.

- Lubricate Hinges – Applying a high-quality lubricant minimizes friction, reduces wear, and prevents squeaking or stiffness in movement.

- Reinforce Weak or Damaged Posts – If the gate post is shifting or unstable, concrete reinforcements or bracket reinforcements may be needed to stabilize the structure.

Track and Roller Adjustments

Sliding gates require well-maintained tracks and rollers for smooth operation. If issues arise, the following repairs are performed:

- Cleaning and Debris Removal – Dirt, leaves, and small stones can obstruct the tracks, leading to operational resistance. Thorough cleaning ensures an unobstructed path.

- Straightening or Replacing Bent Tracks – Warped or damaged tracks may prevent the gate from sliding properly. Technicians use specialized tools to realign or replace bent sections.

- Lubricating the Rollers and Tracks – Proper lubrication helps minimize friction and wear, ensuring effortless movement.

- Checking the Roller Condition – Worn-out or cracked rollers are replaced to maintain efficiency and prevent further track damage.

Automatic Gate System Repairs

Electric and automated gates rely on advanced mechanisms that require careful troubleshooting and repairs. Technicians perform the following:

- Electrical System Check – Wiring connections are examined for loose or frayed wires, which can lead to operational failures or short circuits.

- Motor Repair or Replacement – If the gate motor is not responding or making unusual noises, it may need repair or replacement.

- Sensor Calibration and Adjustment – Misaligned or dirty sensors can cause the gate to fail to detect obstacles or stop responding correctly. Adjustments and cleaning ensure optimal performance.

- Battery and Power Supply Inspection – Backup batteries, power sources, and transformers are tested to ensure uninterrupted operation during power outages.

- Reprogramming and Software Updates – If the control system is malfunctioning, it may need reprogramming or a firmware update to restore full functionality.

Preventative Maintenance for Metal Gates in Walnut Creek, CA

Metal gates are a valuable addition to any property, providing security, convenience, and curb appeal. However, without proper upkeep, they can deteriorate over time due to exposure to the elements, daily use, and mechanical wear. To maximize the lifespan of your metal gate and reduce the need for costly repairs, implementing a regular maintenance routine is essential. Below are some key preventative maintenance steps to keep your gate in optimal condition:

Regular maintenance is key to extending your metal gate’s lifespan and avoiding frequent repairs. Some essential maintenance tips include:

1. Lubricating Moving Parts

The hinges, rollers, and motorized components of your metal gate experience constant movement, which can lead to friction and wear over time. Applying a high-quality lubricant to these moving parts on a regular basis reduces strain, prevents squeaking noises, and extends the longevity of these components. Be sure to use a lubricant designed for metal gates to ensure smooth operation and prevent the buildup of dirt and debris.

2. Cleaning and Painting to Prevent Rust

Dirt, dust, and moisture accumulation can accelerate corrosion, especially in humid or rainy climates. Regularly cleaning the gate with mild soap and water helps remove debris that could contribute to rust formation. Additionally, applying a fresh coat of rust-resistant paint or a protective sealant creates a barrier against moisture, UV rays, and environmental pollutants, keeping your gate looking new while also preventing structural damage.

3. Inspecting Electrical Components

If you have an automatic gate system, routine inspections of the electrical components are crucial. Check the gate motor, control board, safety sensors, and remote access system for signs of wear, loose connections, or malfunctions. Ensuring that these parts are functioning correctly can prevent unexpected breakdowns and costly repairs. If you notice any irregularities, such as slow operation or unresponsiveness, consulting a professional technician may be necessary.

4. Tightening Loose Hardware

Over time, screws, bolts, and brackets can become loose due to vibrations and frequent usage. Inspecting these components and tightening them as needed will help maintain the stability of your gate and prevent misalignment issues. A properly aligned gate operates smoothly and reduces strain on its mechanical and electrical parts, further extending its lifespan.

FAQs About Metal Gate Repair

How do you fix a metal gate?

Fixing a metal gate depends on the type of issue. Common repairs include:

- Rust removal: Sanding or using a rust remover to eliminate corrosion, followed by priming and repainting.

- Hinge repair: Tightening or replacing loose or broken hinges.

- Structural fixes: Welding cracks or broken sections.

- Alignment issues: Adjusting the gate or its posts to ensure smooth opening and closing.

How long do metal gates last?

Metal gates can last 20 to 50 years or more, depending on the material, environmental exposure, and maintenance. Regular upkeep, such as rust prevention and repainting, can significantly extend their lifespan.

What can cause the rusting of a metal gate?

Rusting occurs due to oxidation, often caused by:

- Exposure to moisture (rain, humidity, snow).

- Salt accumulation, especially in coastal areas.

- Lack of protective coatings (paint, primer, or sealant).

- Contact with corrosive chemicals or pollutants.

What is the most suitable metal for metal gates?

The best metal depends on durability and rust resistance:

- Wrought Iron: Strong and decorative but prone to rust without maintenance.

- Steel: Sturdy and durable, especially galvanized steel for rust resistance.

- Aluminum: Lightweight, rust-resistant, and low-maintenance, though not as strong as steel or iron.

How do you protect a metal gate from rust?

To prevent rust and prolong the life of a metal gate:

- Apply a rust-resistant primer and paint to create a protective barrier.

- Use a sealant or powder coating for extra protection.

- Regularly clean and inspect for early signs of rust.

- Keep the gate dry by ensuring proper drainage around it.

- Use rust inhibitors or protective sprays for additional corrosion resistance.

Conclusion

Metal gate repair in Walnut Creek, CA, is essential to maintaining the security, functionality, and aesthetic appeal of your property. Whether your gate has rust damage, alignment issues, or electrical malfunctions, timely repairs can prevent further damage and costly replacements. Understanding the repair process and common issues helps homeowners and business owners make informed decisions about their gate maintenance.

If your metal gate is malfunctioning, trust the experts at Rolling Gates in Walnut Creek, CA. Professional repairs ensure durability, security, and smooth operation. Contact us today to restore your gate’s functionality!

End Note

Rolling Gates offers reliable repair services, including expert metal gate repair in Walnut Creek, CA. From hinge adjustments and motor repairs to track replacements, our skilled technicians are equipped to handle all your gate repair needs with precision and care. We serve a broad service area and are committed to delivering top-notch residential and commercial property solutions.

For more details on our expertise, check out our FAQs on electric gates or browse our gallery for previous projects. Ready to restore your metal gate? Contact us today for expert gate repair and maintenance services in Walnut Creek, CA!