Searching for the best sliding gate repair in Walnut Creek, CA? Trust the pros at Rolling Gates for fast, reliable, and lasting fixes! Get your gate running smoothly—call now for a free consultation!

A sliding gate provides security and convenience for residential and commercial properties in Walnut Creek, CA. However, just like any mechanical system, sliding gates can experience wear and tear over time. From misaligned tracks to electrical malfunctions, several issues can disrupt the functionality of your gate, leaving your property vulnerable. When your sliding gate isn’t working properly, finding a trusted sliding gate repair service in Walnut Creek, CA, is crucial to restoring security and efficiency.

In Rolling Gates, we specialize in comprehensive sliding gate repair services. Whether your gate has stopped moving, makes unusual noises, or struggles to close properly, our experienced technicians can diagnose and resolve the issue promptly. In this guide, we’ll explore common sliding gate problems, effective repair solutions, and how to maintain your gate for long-term performance. If you need immediate assistance, don’t hesitate to contact us for professional sliding gate repair in Walnut Creek, CA.

Top Sliding Gate Problems in Walnut Creek, CA – And How to Fix Them!

Like any mechanical system, sliding gates can experience various issues over time due to weather conditions, daily usage, and lack of maintenance. If your gate malfunctions, it can become a significant inconvenience and security risk.

Below are some of the most common sliding gate problems, their causes, and how to fix them:

1. Misaligned or Damaged Tracks

One of the most frequent issues with sliding gates is track misalignment or damage. Over time, dirt, debris, and physical impact—such as accidental bumps from vehicles or heavy objects—can shift or bend the gate’s tracks, making it difficult to slide smoothly. A misaligned track can cause the gate to drag, get stuck, or even derail.

Signs of a Misaligned Track:

- The gate is difficult to open or close

- It stops abruptly or gets stuck midway

- The gate appears tilted or unsteady

- Grinding or scraping noises while moving

Solution:

A professional gate repair technician will first inspect the tracks for any obstructions, bends, or misalignment. In many cases, a simple cleaning and realignment can restore smooth operation. However, if the track is severely bent or damaged, replacing it may be the best option. Regular maintenance, such as clearing debris and lubricating the track, can help prevent misalignment issues in the future.

2. Worn-out or Broken Rollers

The rollers are a crucial component of a sliding gate, allowing it to glide effortlessly along the track. However, due to constant movement, they can wear out, accumulate dirt, or break over time. When this happens, the gate may become increasingly difficult to operate or may not move at all.

Signs of Worn-Out Rollers:

- The gate feels heavy and requires excessive force to move

- Jerky or uneven motion

- Rollers appear cracked, chipped, or loose

- Squeaking or grinding noises

Solution:

Replacing the damaged rollers with high-quality, durable ones will restore smooth movement. It’s also recommended to lubricate the rollers regularly to prevent premature wear and tear. If the rollers are frequently wearing out, a technician should inspect the overall alignment of the gate and track to ensure there are no underlying structural issues.

3. Gate Motor Failure

For automatic sliding gates, the motor is the heart of the system. If the motor fails, the gate will not open or close properly, leaving your property either vulnerable or inaccessible. Motor failures can be caused by various factors, including electrical issues, general wear and tear, overheating, or exposure to moisture.

Signs of Motor Issues:

- The gate is unresponsive to commands

- The motor makes a humming sound but doesn’t operate

- The gate stops moving halfway through

- Burning smell or signs of overheating

Solution:

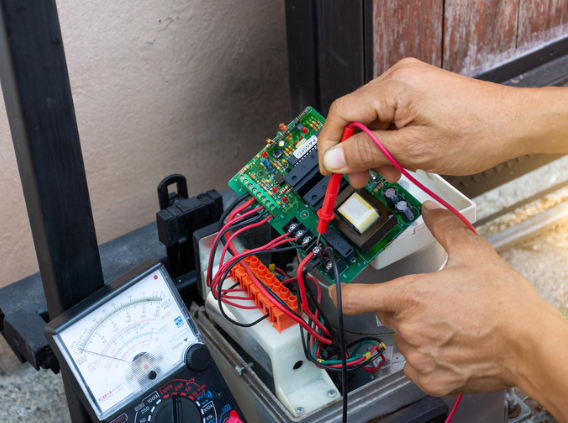

A technician will inspect the motor to diagnose the problem. This may involve checking for faulty wiring, overheating, or mechanical wear. If the issue is minor, repairs or component replacements (such as a circuit board or capacitor) may be sufficient. However, if the motor is extensively damaged or has reached the end of its lifespan, replacing it with a new, more efficient motor is recommended. Regular maintenance and keeping the motor protected from rain and debris can extend its lifespan.

4. Sensor and Remote Control Malfunctions

Modern sliding gates rely on sensors and remote controls for automated operation. If your gate is not responding to commands or stops midway, the problem could be related to the sensors, remote control, or signal interference.

Common Causes of Sensor & Remote Issues:

- Dirt or debris blocking the sensors

- Dead batteries in the remote control

- Interference from nearby electronic devices

- Faulty wiring or a malfunctioning control board

Solution:

First, clean the sensors to remove any dirt or debris that could be obstructing the signal. If the issue persists, replace the remote control batteries or reprogram the system. In some cases, a faulty remote may need to be replaced entirely. If the gate still doesn’t respond, a technician can inspect the wiring and electronic components to diagnose and fix any underlying electrical issues.

5. Rust and Corrosion

Walnut Creek’s climate, with its mix of dry summers and occasional rain, can lead to rust and corrosion on metal gate components. Rust can weaken the gate structure, affect moving parts, and cause premature mechanical failure.

Signs of Rust and Corrosion:

- Visible rust patches on the gate or hardware

- Gate movement becomes rough or uneven

- Components, such as hinges or bolts, appear weakened

- Metal parts flake or break apart

Solution:

Regular maintenance is key to preventing rust damage. This includes applying rust removal treatments, sanding off any rust spots, and applying protective coatings or paint to exposed metal surfaces. Using stainless steel or galvanized components can also help prevent rust buildup. If any parts are severely corroded, they should be replaced immediately to avoid further deterioration.

Effective Solutions for Sliding Gate Repair in Walnut Creek, CA

Routine Maintenance and Inspection

Preventative maintenance is key to avoiding costly repairs and ensuring your gate operates efficiently for years to come. Regular inspections help identify minor issues before they turn into major, more expensive problems. Some important maintenance steps include:

- Lubricating Moving Parts: Hinges, rollers, and chains should be lubricated periodically to reduce friction and wear. Using a high-quality lubricant can enhance performance and prevent premature failure.

- Checking Electrical Connections: If your sliding gate operates electronically, inspecting the wiring, control boards, and sensors is vital. Loose or damaged connections can lead to erratic behavior or a complete system failure.

- Cleaning the Tracks and Pathway: Dirt, debris, and rust accumulation in the tracks can obstruct the gate’s movement, leading to unnecessary strain on the motor. Regularly clearing the tracks ensures smooth operation.

- Testing Safety Features: Modern sliding gates come with sensors and automatic stop functions. Ensuring these features are in working order helps prevent accidents and enhances security.

By implementing a consistent maintenance routine, you can significantly extend the lifespan of your sliding gate and reduce the need for costly repairs.

Professional Diagnosis and Repairs

While DIY repairs may seem like a cost-saving approach, they can sometimes lead to further complications, especially if the root cause of the problem isn’t correctly diagnosed. Hiring a professional technician offers several advantages:

- Accurate Problem Identification: A trained expert can pinpoint issues that may not be immediately visible to an untrained eye.

- Advanced Tools and Techniques: Professional repair services use specialized tools and equipment to address problems efficiently.

- Long-Term Solutions: Instead of temporary fixes, experts focus on providing durable, long-lasting repairs that enhance the overall functionality of your gate.

- Safety Assurance: Sliding gates are heavy and can pose safety hazards if not handled correctly. Professionals have the necessary experience to repair them safely and effectively.

If your gate is making unusual noises, moving slowly, or not operating at all, scheduling a professional inspection is the best course of action.

Upgrading to High-Quality Parts

One of the main reasons sliding gates experience frequent malfunctions is the use of low-quality or worn-out components. Investing in high-quality parts not only improves reliability but also enhances the gate’s overall performance. Consider upgrading the following components:

- Rollers: High-quality rollers ensure smooth and consistent movement, reducing friction and wear.

- Motors: A powerful and efficient motor prevents strain on the system, reducing the likelihood of breakdowns.

- Tracks: Durable tracks provide a stable guide for the gate, ensuring it remains aligned and operates smoothly.

- Remote Control Systems: Upgrading to a modern remote control system with enhanced security features can make gate operation more convenient and secure.

Using premium materials may have a higher initial cost, but it pays off in the long run by reducing maintenance and replacement expenses.

Emergency Gate Repair Services

A malfunctioning sliding gate can compromise security, inconvenience residents, and disrupt business operations. When unexpected breakdowns occur, having access to reliable emergency repair services is crucial.

Rolling Gates offers same-day repair services in Walnut Creek, CA, to minimize inconvenience and security risks. Whether it’s an issue with the motor, track misalignment, sensor failure, or any other problem, our team is ready to assist you promptly. We understand that a non-functional gate can pose security risks, so we work efficiently to get your gate back in working order as soon as possible.

FAQs About Sliding Gate Repair

How to maintain a sliding gate?

Proper maintenance of a sliding gate is essential for its long-term performance and to avoid costly repairs. Start by regularly cleaning the tracks to remove debris, dirt, and other obstructions that could hinder smooth operation. Lubricate all moving parts, such as rollers, hinges, and chains to prevent wear and reduce friction. Routinely check for loose or damaged bolts, screws, and brackets, tightening or replacing them as necessary. Inspect the motor, sensors, and control panel to ensure they are functioning correctly and are free of dirt or moisture that could cause electrical issues. Periodic inspections, at least every few months, can help you detect small problems early before they turn into major issues.

Why is my sliding gate not closing properly?

If your sliding gate is not closing properly, several factors could be at play. One common issue is a misaligned track, which prevents the gate from moving smoothly. Obstructions such as debris, leaves, or small objects in the track can also block the gate’s path. Sensor obstructions, such as dirt covering the sensor eye, can cause it to misread signals and prevent proper closure. The motor may be malfunctioning due to wear, electrical problems, or power issues. Ensure that the track is level, check for blockages, and inspect the motor, electrical wiring, and sensors for damage. In some cases, a professional may be needed to identify and fix complex electrical or mechanical failures.

What advantage does a sliding gate have over a swing gate?

Sliding gates are ideal for properties with limited space as they don’t require a large clearance to open. They also offer better security, operate more smoothly in high-wind areas, and are generally more durable for heavy-duty applications.

What keeps a sliding gate from falling?

Sliding gates are secured by guide rollers, tracks, and end stops that keep them in place. Additionally, a properly installed gate will have a strong support post and anti-drop mechanisms to prevent it from falling off the track.

What is the problem with sliding gates?

Common problems with sliding gates include track obstructions, motor failures, sensor misalignment, and wear on rollers or chains. Weather conditions like dirt buildup or extreme temperatures can also affect smooth operation. Regular maintenance can help minimize these issues.

Conclusion

A well-functioning sliding gate is essential for security and convenience. Whether it’s a misaligned track, motor failure, or worn-out rollers, timely repairs can prevent further damage and ensure smooth operation. If you’re experiencing any issues with your sliding gate, seeking professional repair services in Walnut Creek, CA, is the best way to ensure reliability and longevity.

Rolling Gates in Walnut Creek, CA, provides expert sliding gate repair solutions tailored to your needs. Our skilled technicians use top-quality parts and advanced repair techniques to restore your gate’s functionality. Contact us today for a consultation and experience top-notch service in Walnut Creek, CA.

End Note

Rolling Gates in Walnut Creek, CA, is your trusted partner for all gate repair and maintenance needs. We stand behind our work with a warranty on all repairs, ensuring that your gate remains in excellent condition for years. Whether you need sliding gate repairs, gate opener services, or general maintenance, our team is ready to assist.

Explore our services on our website and check out our gate repair solutions, gate openers, and our service areas. Have questions? Visit our FAQ section or browse our gallery to see our work. Ready to schedule a repair? Contact us today for professional sliding gate repair in Walnut Creek, CA.